Battery regulations are all about safety

To bring a battery or a battery-powered device to market, compliance with regulations is essential. Before you can sell batteries and battery-powered devices, you must comply with a laundry list of regulations and standards. Batteries have to meet various safety standards to be sold in different jurisdictions. Aside from the ubiquitous UL mark, ANSI, UN, DOT, and IEC standards are very common.

To meet any or all of these standards, batteries have to undergo safety tests in use and abuse conditions. In this article, we'll look at some of the most common battery standards used worldwide and the safety tests they require.

In previous articles, we’ve discussed how peripheral circuitry and devices like battery management systems and thermal management systems provide essential safeguards and improve performance. These systems and many other facets of battery design contribute to economics in complex ways, including their effect on long-term ROI. These details of battery design also enable batteries to enter the marketplace by helping them pass safety tests.

Don’t stress about navigating the regulatory environment. Instead, turn to Aved’s team of battery experts. We’ll design a battery based on your needs, engineer it to pass all relevant safety tests, and help you through the testing and certification process. Contact us with questions or request a quote today.

Understanding battery regulations and standards

Navigating the rules and regulations for battery safety can be very confusing. The list of different rules can feel endless, and determining which ones apply in which situations is a chore. Let’s look at the basics of battery regulations.

How standards work

Multiple private and public organizations publish safety standards different kinds of batteries must meet. Many or most of these don't necessarily carry the force of law. Often, they are optional industry benchmarks.

However, as OSHA explains here, the so-called optional standards that constitute industry consensus play important roles in determining compliance and liability in legal settings. They are not, in fact, optional. What is more, governments worldwide adopt and enforce different standards, limiting what kinds of devices can be imported and sold under their jurisdiction.

Numerous standards and regulatory organizations exist worldwide. In this article, we’ll focus on a few big names that you’re almost guaranteed to encounter:

- The United Nations (UN)

- The US Department of Transportation (DOT)

- UL, formerly known as Underwriter's Laboratories

- The American National Standards Institute (ANSI)

- The International Electrotechnical Commission (IEC)

Groups like these frequently publish multiple standards for multiple kinds of batteries and the devices in which they are used. For instance, lithium-ion chemistries frequently receive separate treatment. Electric vehicle batteries, medical device batteries, and consumer-use batteries are frequently held to different standards.

These standards often exist in parallel to one another, covering similar or identical situations. In some cases, harmonization and mutual recognition of standards has helped to reduce regulatory clutter.

Safety testing—the heart and soul of battery standards

Many of these standards promote uniformity of terminology and construction in batteries. The interchangeability of vocabulary and parts are, after all, hallmarks of the modern world.

When it comes to battery safety, though, the name of the game is testing. These standards don’t necessarily tell you how to make your battery safe. Instead, they tell you how to know if it isn’t safe: use and abuse testing.

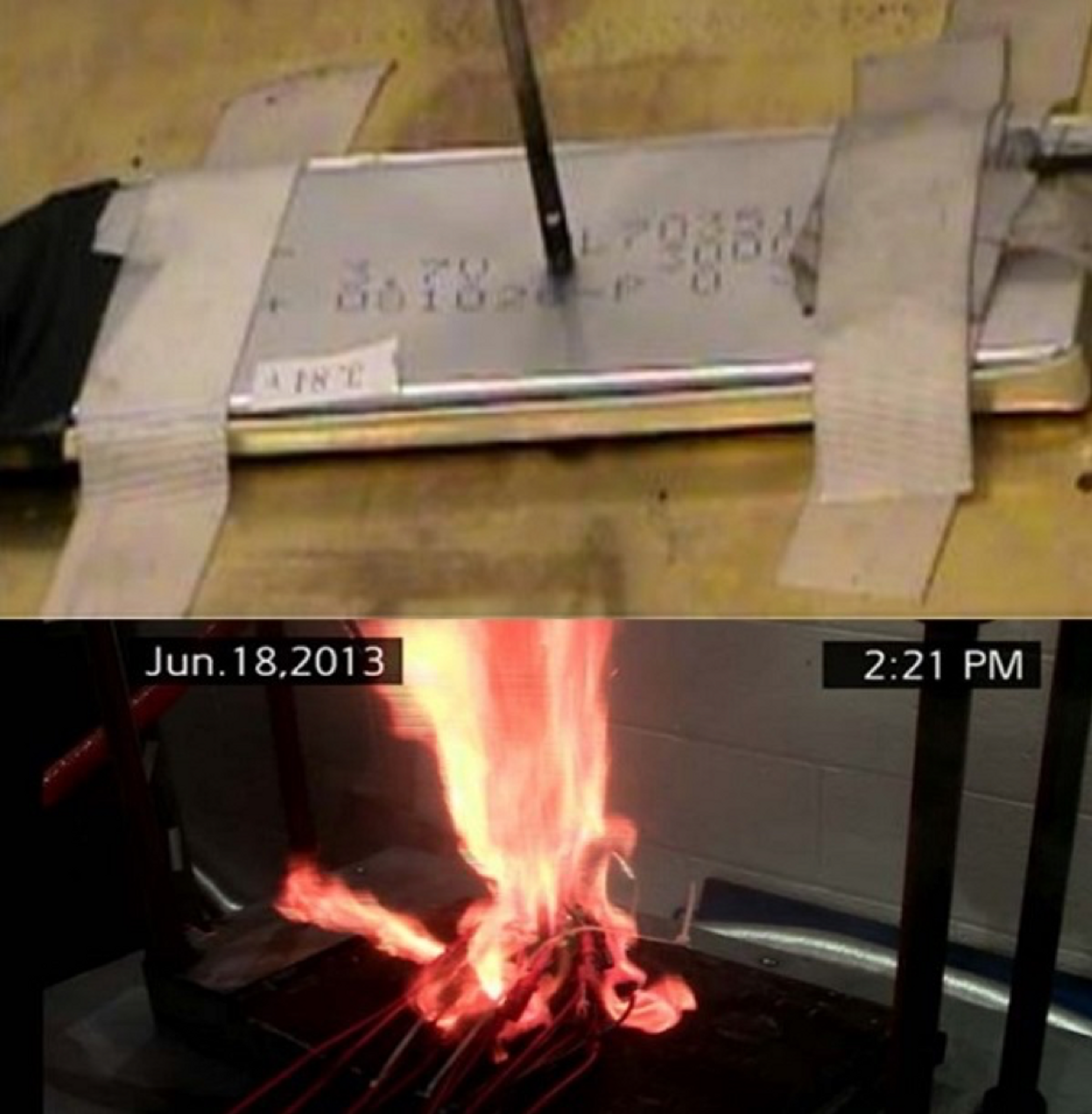

Testing laboratories subject sample batteries to a range of tests that might create a hazard, such as a puncture (top). Bursting into flames (bottom) is a common failure condition. Image source: Energy.gov

To certify a battery to a particular standard, you must submit samples to a lab authorized to perform tests. Frequently, that means Nationally Recognized Testing Laboratory (NRLT) as designated by OSHA. The lab takes the samples and subjects them all sorts of abuses—short circuits, extreme heat, overcharge, puncture, open flames, etc.—and checks for failure. Each standard has precise definitions for failure, but catching fire and exploding are sure signs.

UN and DOT rules for shipping lithium batteries

If you want to ship your lithium batteries by air, truck, or train (whether in or out of the US), you'll have to meet certain United Nations requirements. Section 38.3 of the UN Manual of Tests and Criteria (7th revised edition, 2019)—UN 38.3 is a model standard for lithium ion and lithium metal batteries enforced in many countries.

Certification to UN/DOT 38.3 is essential for remaining compliant when shipping lithium batteries.

This standard has been adopted by the US Code of Federal Regulations (CFR) and is enforced by the US Department of Transportation (DOT) has adopted this standard. Thus, it often referred to as UN/DOT 38.3. Its requirements harmonize with the US Federal Aviation Administration (FAA) and International Air Transport Association (IATA).

UN 38.3 applies only to lithium ion and lithium battery chemistries—a pattern that reappears in many other standards. Because of their inherent flammability, lithium chemistries are more regulated than other battery chemistries.

UN 38.3 features a battery of tests performed in succession on a single battery pack or cell. On their own, each of these tests might not be difficult to pass, but accumulation of damage can lead to failures. To pass, batteries must not fail while or after being subjected to, in order:

- A test simulating altitude and reduced pressure

- Cycling between +72 C and -40 C repeatedly

- Rapid vibration in 3 dimensions

- Physical shock (Quick acceleration/deceleration)

- External short circuit after heating

Separate, non-damaged batteries or cells also have to undergo impact/crush tests, overcharge tests, and forced discharge tests. For all these tests, a number of sample batteries are tested at different states of charge.

UL standards for battery safety

Perhaps the most famous standards and testing organization is UL, formerly known as Underwriters Laboratories. With status from OSHA as an NRLT, UL simultaneously sets industry standards and tests devices to determine compliance. The ubiquitous UL mark is synonymous with safety.

UL is an NRLT and recognized globally as a leader in the safety testing industry. Their mark signifies safety and reliability.

UL has myriad standards for electronic equipment. For batteries, there are 5 standards that apply to the most common applications:

- UL 2054: Household and Commercial Batteries

- UL 1642: Lithium Batteries

- UL 2271: Batteries for Use in Light Electric Vehicle Applications

- UL 2595: General Requirements for Battery Powered Appliances

- UL 2580: Batteries for Use in Electric Vehicles

Primary among these is UL 2054. "Household and commercial batteries" is a broad scope, and passing the tests of this standard is a requirement of many other standards for end-use devices. Some overlap exists between UL 2054 and UL 1642, the standard for lithium batteries. For cell-level testing, UL 2054 defers to UL 1642.

The tests required by UL 2054 are extensive and include electrical, mechanical, structural, and fire safety tests such as short-circuit, overcharge, forced discharge, drop, crush, vibration, thermal shock, and exposure to an open flame.

While it is a mainstay of battery safety testing, the future of UL 2054 is uncertain because of competing standards, namely IEC 62133. A publication of the International Standards Organization (IEC), IEC 62133 has global recognition, is cited in numerous end-device standards, and occupies a similar regulatory space to UL 2054. This creates frustration because the two standards do not require the same tests.

As of 2017, UL has published the second edition of UL 62133, a document fully harmonized with IEC 62133. Yet UL 2054 is still required by other standards, so the phasing-out schedule remains uncertain.

The electric vehicle industry is covered by two UL standards: UL 2271 and UL 2580. UL 2271 is the standard for Batteries in Use in Light Electric Vehicle Applications, and it applies to things like powered wheelchairs and e-bikes. UL 2580: Batteries for Use in Electric Vehicles applies to full-size electric cars.

ANSI’s standard for portable secondary cells and batteries

Unlike the other organizations here, American National Standards Institute (ANSI) does not write standards themselves. Instead, they promote and certify the development of voluntary industry standards by industry organizations.

Their document Portable Rechargeable Cells and Batteries (ANSI C18.2M) provides core guidance for manufacturers of secondary cells and batteries of nickel-cadmium, nickel-metal hydride, and lithium-ion chemistries. Part 1 of this document focuses on standardization, both physical and electrical, in order to promote the interchangeability of rechargeable batteries.

Like other standards we've mentioned here, Part 2 of ANSI C18.2M is about safety standards and acceptance testing. Tests are divided into anticipated use tests and reasonably foreseeable abuse tests. Anticipated use tests include altitude tests, thermal shock tests, vibration tests, and mechanical shock tests. The abuse tests are for short circuit, forced discharge, impact, and crush.

Aved can help you navigate the regulatory environment

The basics of battery safety testing and certification are simple. Approved laboratories put sample batteries are put through their paces, subjecting them to all manner of abuses. Thermal abuse, puncture, physical shock, and short circuit are just a few examples of tests that might be conducted. To pass the test, batteries have to survive the abuse conditions without failing. "Failure" can mean many things, but catching fire and exploding are two sure signs that the battery isn't safe enough for market.

The basics are simple, but the specifics of battery safety testing and certification can be extremely complicated. Whose standards do you need to meet? There are many options—UN, UL, ANSI, IEC, and more. Plus, each of these organizations published multiple documents. Which standard applies? The answers to these questions depend on the chemistry of your battery, its size and format, what the end device is, and where you want to bring the battery to market, among other things.

Turn to Aved’s team of battery experts to help you navigate this process. As a part of our start-to-finish battery pack design and manufacturing services, we'll design battery packs based on your end-use needs, identify the relevant safety standards that you need to meet to bring your product to market anywhere in the world, and engineer the batteries to pass applicable use and abuse tests. To get started on your custom battery solution, contact us to discuss you project or request a quote today.